PRODUCT

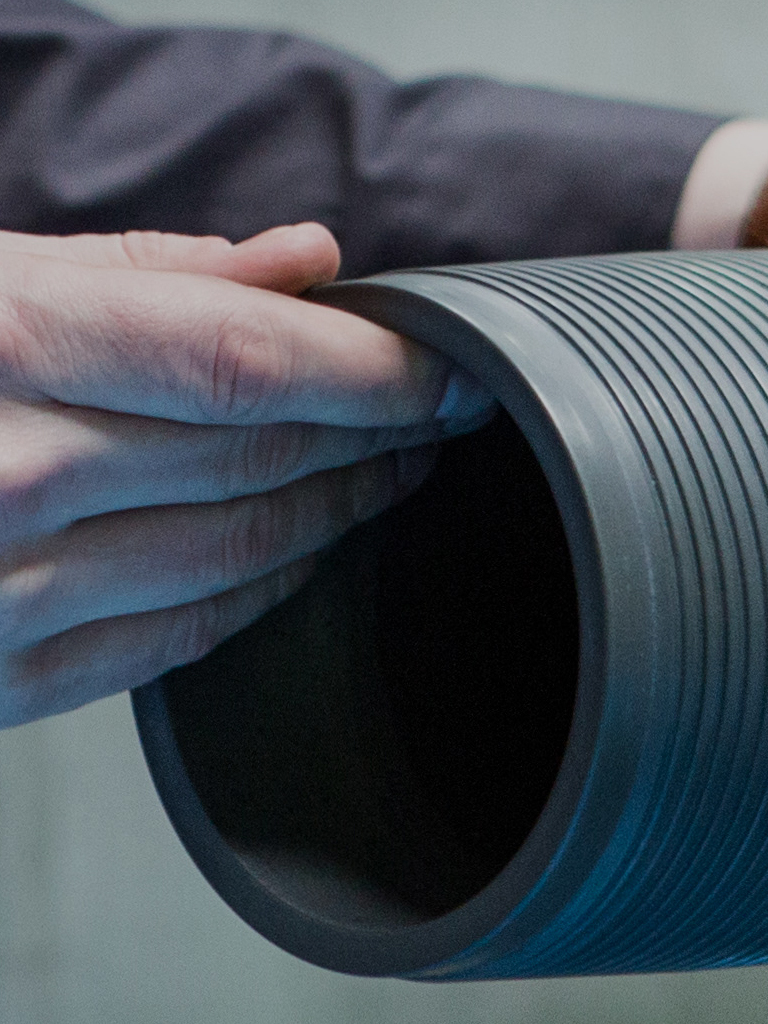

TP-G4 The Lastest Fourth Generation Premium Connection

Sizes: 5in~14-3/8in

High Performance Gas-Tight Connection

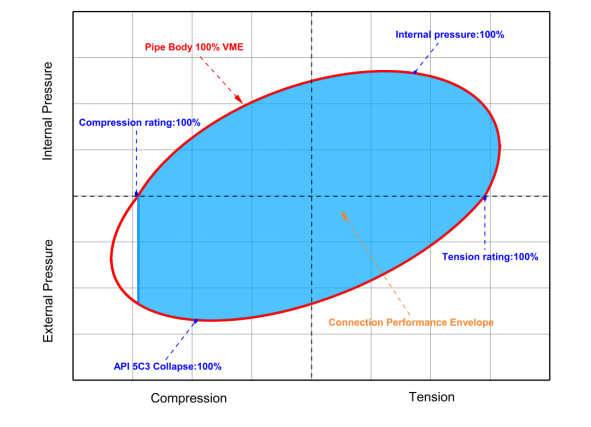

Performance meet four-100%(tension, compression, internal and external pressure)

Thread crest parallel to axis design, easy to make up.

New concept sealing structure ensures excellent gas sealing ability under combined load, and improves the over-torque ability.

Suitable for complex well conditions such as horizontal well and extended reach well.

Suitable for high grade steel and high alloy materials.

Options:

TP-G4 HT: High Torque

TP-G4(SC): Special Clearance

1. Description

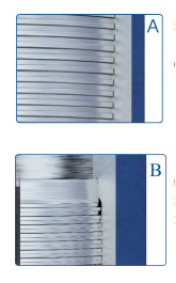

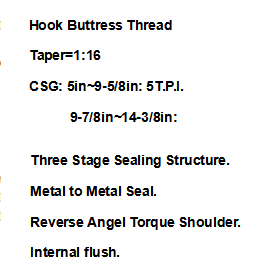

1.1 Threaded Connection

Unique golden section proportional tooth shape design, uniform and harmonious thread structure size, stable mechanical structure and excellent bearing performance.

The negative angle bearing design is adopted, with excellent connection performance and 100% bending and compression resistance.

Optimized hook thread design reduces thread collision.

Stepped thread design, easy to make up and not easy to cross thread.

1.2 Sealing Structure

The design of new concept sealing structure improves the leakage resistance of the joint.

The main seal and auxiliary seal adopt non equivalent interference design, highlighting the advantages of the main seal.

1.3 Reverse Angle Torque Shoulder

Negative angle shoulders provide accurate screw positioning.

1.4 Streamlined Internal Profile

The streamlined internal profile minimizes turbulence and energy loss when high-velocity gas flows.

1.5 Coupling Design

The coupling performance meets 100% design requirements, and the outer diameter design is consistent with API standard,

1.6 Connection Low Stress Design

The lower stress design makes the connections reliable in Corrosive condition.

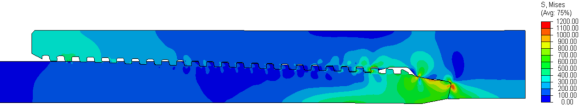

2. Finite Element Analysis on TP-G4

Circumferential stress

The low stress design of the joint makes TP-G4 the best choice for corrosive environment applications.

VME

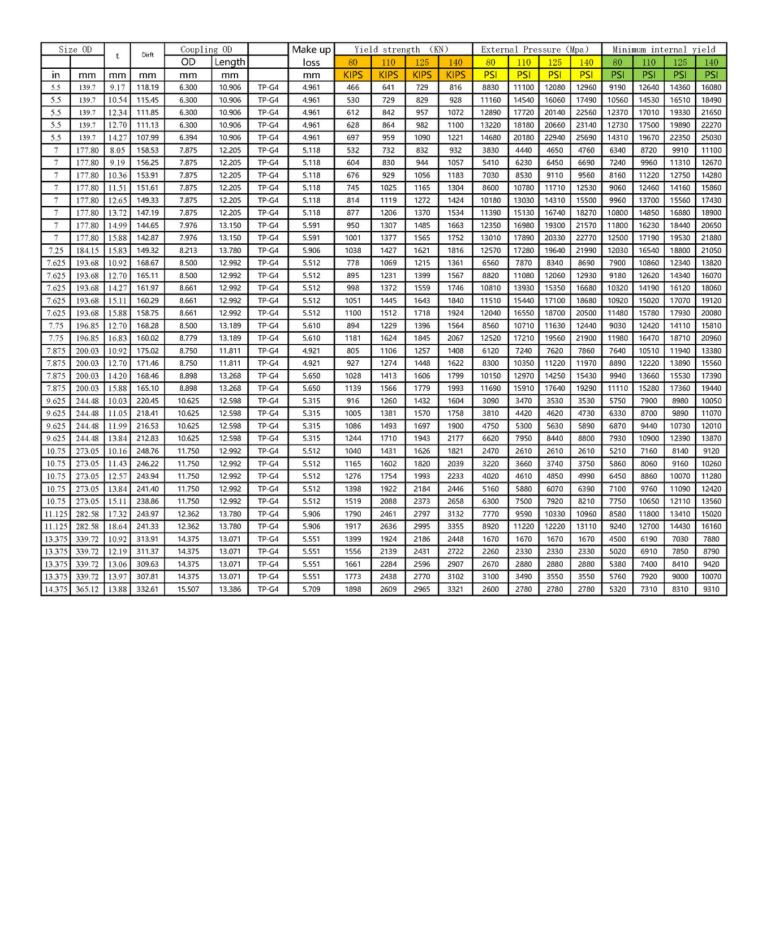

Performance of TP-G4 Connection