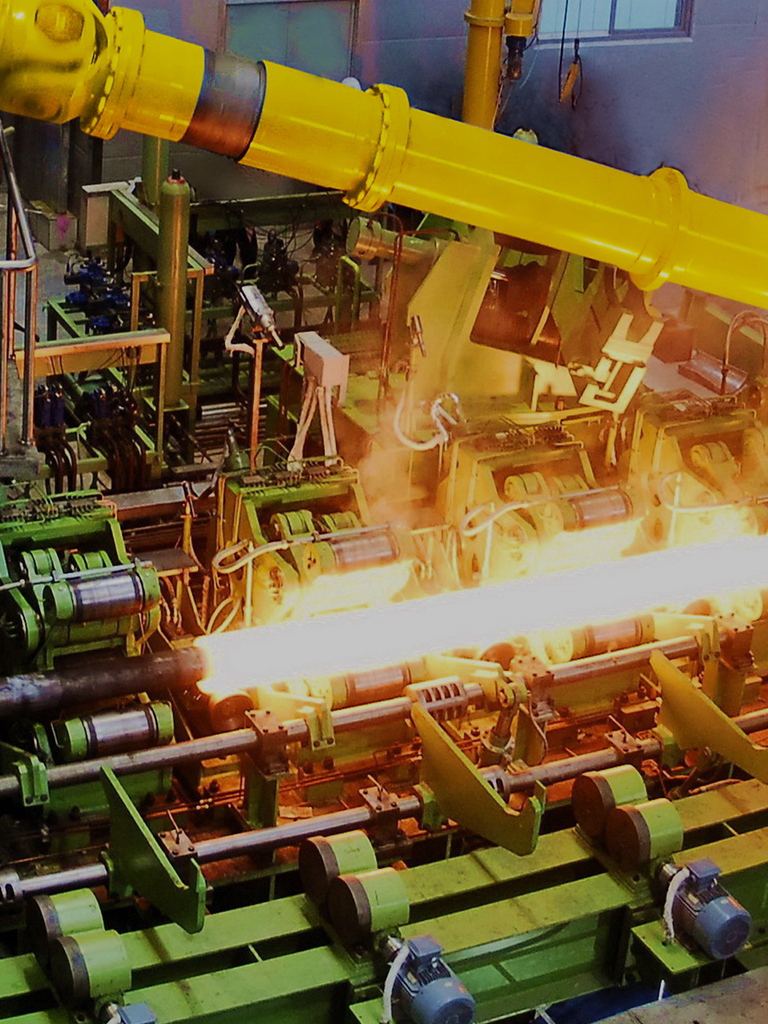

PRODUCTION SITE

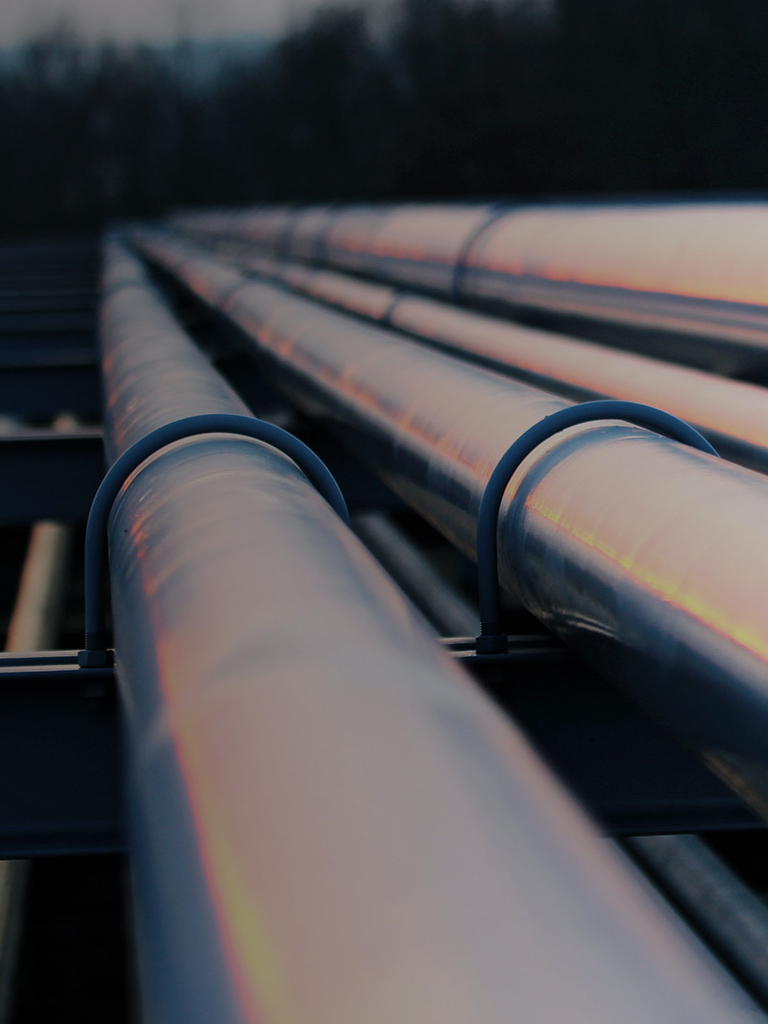

TPCO(T) runs 24 pipe finishing lines, mainly including: 14 casing and tubing lines, 6 plain-end pipe lines (for line pipe and P.E. OCTG), 1 tubing upsetting line, 3 coupling lines.

Main equipment:

CNC threading machines,chamfering machines,hydraulic testing machines,NDTs,saws,coupling screw-up machine, coupling phosphate line, up-setter, marking/measuring/weighing devices, and others.

CNC threading machines: introduced from U.S.A., Belgium, Spain, Germany and Japan.

Non-Destructive Tests:

Various NDT technologies are adopted in TPCO for detection of transversal, longitudinal and lamination defects in the inner and outer surfaces of pipe body, pipe end and coupling, including electro-magnetic, ultrasonic, magnetic particle, eddy current, to ensure that all pipes supplied to the customers are of high quality.