PRODUCT

TP-NF┃5”~11-3/4”

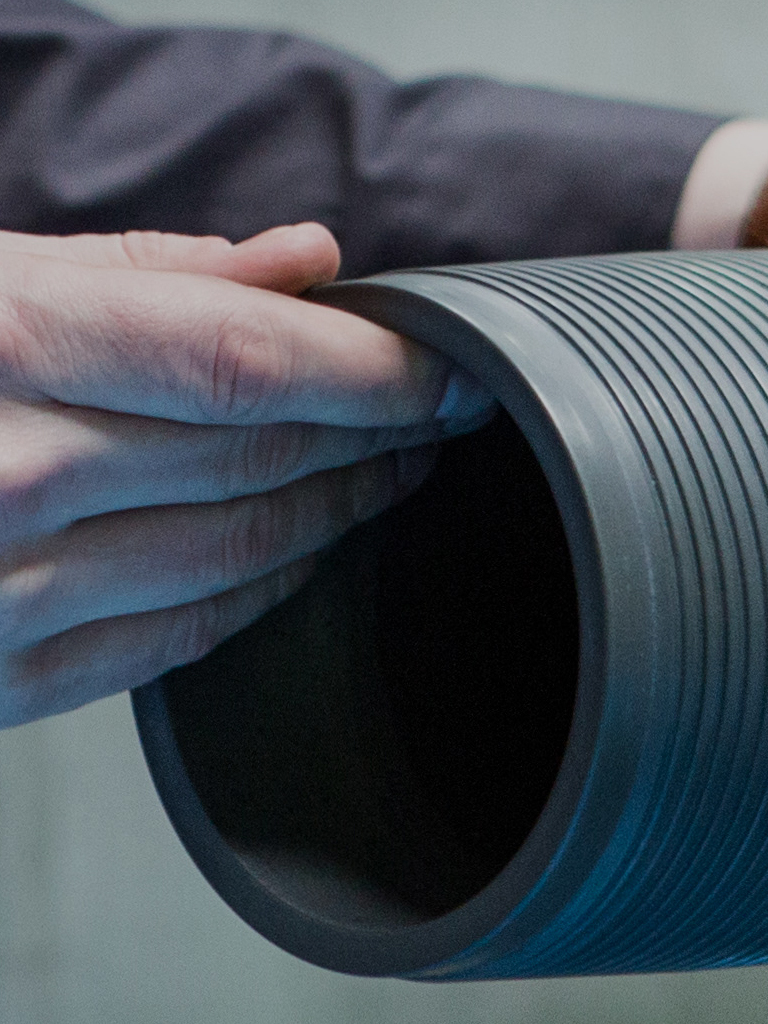

Slim designed coupling

Coupling OD is slightly greater than pipe OD

Metal-to-Metal seal

Reverse angel torque shoulder

■Slim design coupling provides optimum clearance

■Metal-to-Metal seal provides reliable gas-tight seal-ability

■T&C design eliminate swaged pin end or expansion box end

■Field repair friendly

Description

Threaded Connection

Buttress threads form with a taper of 1:16 and a lead of 5TPI, which can be measured by API gauge. The slim designed coupling provides the optimized clearance.

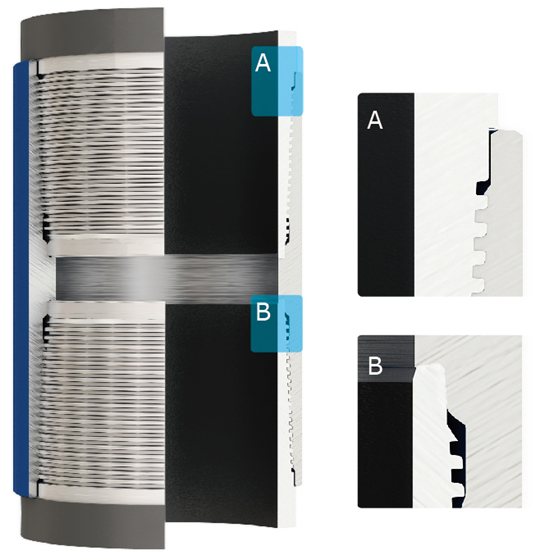

Metal-to-Metal Seal

Metal-to-metal seal surface provides enough contact length and contact pressure. The Metal-to-Metal seal system offers excellent gas-tight sealing, even under the most severe combined loads. The seal integrity remains constant after repeated make-ups and break-outs. Optimized thread geometry minimizes the risk of galling.

Reverse Angle Torque Shoulder

The reverse angle torque shoulder provides a positive torque stop, which allows for accurate power tight make-up and minimizes hoop stresses in the connection. The wedge effect caused by the reverse angle gives the connection a superior structural strength. The shoulder design is optimized in order to resist adverse conditions such as combined compression and external pressure or combined bending, compression and torque.

Internal Profile

The streamlined internal profile minimizes turbulence and energy loss when high-velocity gas flows.

Coupling Design

Because the coupling covers the vanishing threads therefore the connection tensile efficiency is maximized.

Low Stress Design

The lower stress design makes the connections reliable in corrosive conditions.

TP-NF┃T&C Slim Coupling ┃5”~11-3/4”